Reflected light microscopy: Difference between revisions

(e.g.correction) |

(e.g.correction1) |

||

| Line 5: | Line 5: | ||

Reflected light microscopy is frequently the domain of industrial applications, especially in the rapidly growing semiconductor arena and this represents a most important segment of microscopical studies. | Reflected light microscopy is frequently the domain of industrial applications, especially in the rapidly growing semiconductor arena and this represents a most important segment of microscopical studies. | ||

[[File:Mirror image reversal.svg|Mirror image reversal]]]] | [[File:Mirror image reversal.svg|Mirror image reversal]]]] | ||

50% is reflected and 50% is transmitted | |||

Revision as of 21:36, 7 December 2012

Introduce

Polarizing microscopy can be used with reflected and transmitted light. Reflected light is useful for study of opaque materials such as mineral oxides and sulfides, metals and silicon wafers and requires stress-free objectives that have not been corrected for viewing through a coverslip.

Reflected light microscopy is often referred to as incident light, dpi-illumination, or metallurgical microscopy, and is the method of choice for fluorescence and for imaging specimens that remain opaque even when ground to a thickness of 30 micrometers. much like the fluorescense microscope, in reflected bright field microscopy the sample is illuminated from above through the objective.

Reflected light microscopy is frequently the domain of industrial applications, especially in the rapidly growing semiconductor arena and this represents a most important segment of microscopical studies.

]]

]]

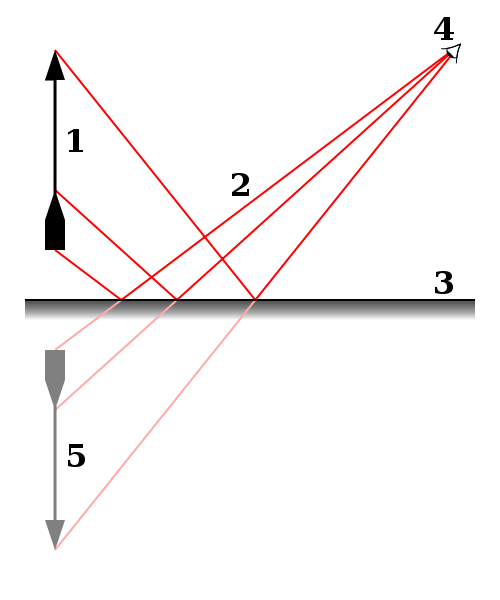

50% is reflected and 50% is transmitted